Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

• Ang mataas na katumpakan at mataas na kahusayan ay maaaring makamit ang mataas na kalidad na ibabaw ng pagproseso ng mga electrodes na tanso.

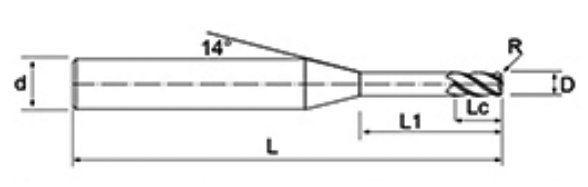

| Hindi. | diameter D | R Anggulo R | Haba ng plauta Lc | Epektibong Haba L1 | Pangkalahatang Haba L | Shank Dia d | Bilang ng Blade F |

| NNX-4RSP-D1-L4 | 1 | 0.1 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.1 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.1 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.1 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.1 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.1 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.1 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.1 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.1 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1-L4 | 1 | 0.2 | 1.5 | 4 | 50 | 4 | 2 |

| NNX-4RSP-D1-L6 | 1 | 0.2 | 1.5 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1-L8 | 1 | 0.2 | 1.5 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1-L10 | 1 | 0.2 | 1.5 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1-L12 | 1 | 0.2 | 1.5 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1-L14 | 1 | 0.2 | 1.5 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1-L16 | 1 | 0.2 | 1.5 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1-L18 | 1 | 0.2 | 1.5 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1-L20 | 1 | 0.2 | 1.5 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.1 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.1 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.1 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.1 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.1 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.1 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.1 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.1 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L6 | 1.5 | 0.2 | 2.3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L8 | 1.5 | 0.2 | 2.3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L10 | 1.5 | 0.2 | 2.3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L12 | 1.5 | 0.2 | 2.3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L14 | 1.5 | 0.2 | 2.3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L16 | 1.5 | 0.2 | 2.3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L18 | 1.5 | 0.2 | 2.3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D1.5-L20 | 1.5 | 0.2 | 2.3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.1 | 3 | 6 | 50 | 4 | 2 |

| NNX-4RSP-D2-L8 | 2 | 0.1 | 3 | 8 | 50 | 4 | 2 |

| NNX-4RSP-D2-L10 | 2 | 0.1 | 3 | 10 | 50 | 4 | 2 |

| NNX-4RSP-D2-L12 | 2 | 0.1 | 3 | 12 | 50 | 4 | 2 |

| NNX-4RSP-D2-L14 | 2 | 0.1 | 3 | 14 | 50 | 4 | 2 |

| NNX-4RSP-D2-L16 | 2 | 0.1 | 3 | 16 | 50 | 4 | 2 |

| NNX-4RSP-D2-L18 | 2 | 0.1 | 3 | 18 | 50 | 4 | 2 |

| NNX-4RSP-D2-L20 | 2 | 0.1 | 3 | 20 | 50 | 4 | 2 |

| NNX-4RSP-D2-L6 | 2 | 0.2 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.2 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.2 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.2 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.2 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.2 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.2 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.2 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D2-L6 | 2 | 0.5 | 3 | 6 | 50 | 4 | 4 |

| NNX-4RSP-D2-L8 | 2 | 0.5 | 3 | 8 | 50 | 4 | 4 |

| NNX-4RSP-D2-L10 | 2 | 0.5 | 3 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D2-L12 | 2 | 0.5 | 3 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D2-L14 | 2 | 0.5 | 3 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D2-L16 | 2 | 0.5 | 3 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D2-L18 | 2 | 0.5 | 3 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D2-L20 | 2 | 0.5 | 3 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.1 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.1 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.1 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.1 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.1 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.1 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.2 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L10 | 3 | 0.5 | 4.5 | 10 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 50 | 4 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 50 | 4 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 50 | 4 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 50 | 4 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 50 | 4 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 60 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 60 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 60 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.2 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.2 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.2 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.2 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.2 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.2 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.2 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D3-L12 | 3 | 0.5 | 4.5 | 12 | 75 | 6 | 4 |

| NNX-4RSP-D3-L14 | 3 | 0.5 | 4.5 | 14 | 75 | 6 | 4 |

| NNX-4RSP-D3-L16 | 3 | 0.5 | 4.5 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D3-L18 | 3 | 0.5 | 4.5 | 18 | 75 | 6 | 4 |

| NNX-4RSP-D3-L20 | 3 | 0.5 | 4.5 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D3-L25 | 3 | 0.5 | 4.5 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D3-L30 | 3 | 0.5 | 4.5 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 05 | 6 | 16 | 60 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 60 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 60 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.2 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.2 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.2 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.2 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.2 | 6 | 35 | 75 | 6 | 4 |

| NNX-4RSP-D4-L16 | 4 | 0.5 | 6 | 16 | 75 | 6 | 4 |

| NNX-4RSP-D4-L20 | 4 | 0.5 | 6 | 20 | 75 | 6 | 4 |

| NNX-4RSP-D4-L25 | 4 | 0.5 | 6 | 25 | 75 | 6 | 4 |

| NNX-4RSP-D4-L30 | 4 | 0.5 | 6 | 30 | 75 | 6 | 4 |

| NNX-4RSP-D4-L35 | 4 | 0.5 | 6 | 35 | 75 | 6 | 4 |

| Serye ng Tool | diameter | Radius | Corner Radius | Haba ng plauta | Epektibong haba | Pangkalahatang haba | Shank Dia | |||

| D | R | CR | Lc | L1 | L | d | ||||

| NNX Carbide End Mills para sa Copper Electrode | D0.1~D0.9 | 0 -0.005 | R0.05~R2 | /-0.005 | CR0.05~CR0.5 | /-0.005 | 0 0.3 | 0 0.3 | 0.5 -0.5 | h5 |

| D1~D3.5 | 0 -0.005 | |||||||||

| D4~D10 | -0.003 -0.015 | R3~R5 | /-0.005 | CR1.0~CR3.0 | /-0.008 | 0 0.5 | 0 0.5 | |||

| D12~D20 | -0.003 -0.018 | R6~R10 | /-0.008 | |||||||

Ang NNX-4RSP 4 flute deep groove round nose end mill para sa copper electrode machining ay nag-aalok ng malawak na hanay ng mga opsyon sa laki, mula sa maliit na diameter hanggang sa malaking diameter, mula sa maikling haba ng gilid hanggang sa mahabang gilid, ang bawat detalye ay maingat na idinisenyo upang matugunan ang mga pangangailangan ng iba't ibang mga kondisyon sa pagtatrabaho. Mahusay man itong pagpoproseso o paggupit sa malalaking lugar, ang nababaluktot na kumbinasyon ng iba't ibang mga sub-modelo ay nagbibigay-daan sa mga user na malayang pumili ng pinaka-angkop na tool upang makamit ang mahusay at tumpak na pagproseso ng copper electrode.

Ang espesyal na deep groove round nose na disenyo ay hindi lamang pinahuhusay ang higpit ng tool, ngunit ino-optimize din ang force distribution ng cutting edge, na epektibong binabawasan ang vibration at burr sa panahon ng pagproseso. Ang kakaibang disenyo ng groove ay nagpapababa ng cutting resistance, tinitiyak ang matatag na pagputol ng mga copper electrode materials sa mataas na bilis, at pinapabuti ang surface finish.

Gumagamit ang tool ng (0.2μm) na ultra-fine particle substrate na may pinakabagong DLC coating technology, na may mahusay na wear resistance at napakababang friction coefficient, na ginagawa itong mas mahusay sa pagpoproseso ng copper electrode. Pinagsama sa ultra-fine grinding technology at ultra-low roughness blade, lubos nitong binabawasan ang problema sa adhesion ng tool at pinapabuti ang buhay ng serbisyo at pagkakapare-pareho ng pagproseso.

Pagtatag ng negosyo

Mga empleyado

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are 4 Flute Deep Groove Round Nose End Mills para sa Copper Electrode Machining Suppliers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional 4 Flute Deep Groove Round Nose End Mills para sa Copper Electrode Machining Factory. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Sasagot kami sa iyo sa loob ng 12 oras pagkatapos matanggap ang pagtatanong sa mga karaniwang araw.

Kami ay mga tagagawa, gumagawa at nagbebenta kami ng aming sarili.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional 4 Flute Deep Groove Round Nose End Mills para sa Copper Electrode Machining Suppliers.

Saklaw ng aming mga produkto ang halos buong industriya ng amag, industriya ng depensa, industriya ng aerospace, industriya ng sasakyan, mga produktong elektroniko at iba pang larangan.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom 4 Flute Deep Groove Round Nose End Mills para sa Copper Electrode Machining.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are 4 Flute Deep Groove Round Nose End Mills para sa Copper Electrode Machining Factory

Una, pagkatapos ng bawat proseso, nagsasagawa kami ng kaukulang mga inspeksyon. Para sa huling produkto, magsasagawa kami ng 100% buong inspeksyon ayon sa mga kinakailangan ng customer at mga internasyonal na pamantayan;

Pagkatapos, mayroon kaming advanced at kumpletong top-notch testing equipment sa industriya, tulad ng spectral analyzer, metallographic microscope, atbp., na maaaring matiyak ang katatagan at pagkakapare-pareho ng mga cutting tool, habang natutugunan ang mataas na katumpakan na mga kinakailangan sa pagsubok ng mga customer para sa mga cutting tool.

Kapag nag-quote, kukumpirmahin namin sa iyo ang paraan ng transaksyon, FOB, CIF, CNF o iba pang mga opsyon. Kapag gumagawa ng maramihan, kadalasan ay nagsasagawa muna kami ng 30% na paunang bayad, at pagkatapos ay binabayaran ang natitirang balanse sa pagpapakita ng bill of lading. Kadalasang ginagamit namin ang T/T bilang paraan ng pagbabayad, ngunit tinatanggap din ang L/C.